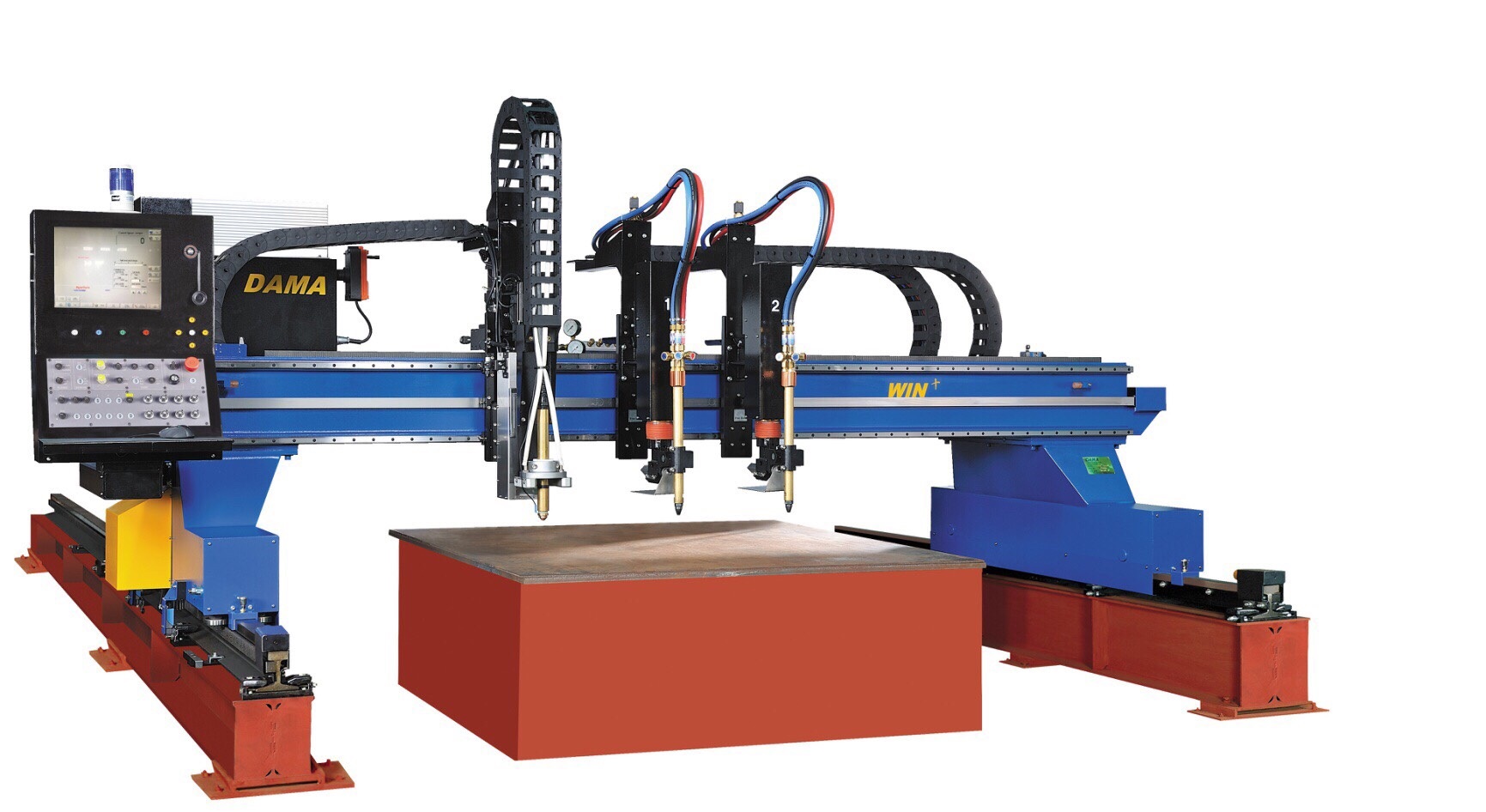

Plasma Cutting Machine

- Compact gantry design for medium duty cutting and with linear guide for the transverse guide (250mmwidth) giving high precision and durability.

- Equipped with high performance AC servo drive system: Positioning speeds up to 15 M/min.

- Transverse energy feed chains: Giving efficient transportation of hoses and cables.

- Sensor THC height sensing system as standard to easy setting for plasma height control.

- With servo motor & ball screw plasma torch lifter.

- Plasma torch break away with magnetism collision protection and auto centering.

- MicroEdge Pro CNC brings Hypertherm's latest hardware and Phoenix software technology to a product that is customizable for a wide variety of applications.

- LCD with touch screen and full color high-resolution graphic display.

- 62 preprogram and choice of CAD/CAM to suit all applications.

- Multiple input for parts program loading, USB and RS-232 /RS422 interface.

- Can direct read CAD's DXF file to do cut.

- Multiple choice for cut loss go-back, easy operation.

|

Model |

WIN+ 2000 |

WIN+ 2500 |

WIN+ 3100 |

WIN+ 3500 |

|

|

Effective cutting width (A) |

2000 mm |

2500 mm |

3100 mm |

3500 mm |

|

|

Rail span (B) |

2600 mm |

3100 mm |

3700 mm |

4100 mm |

|

|

Effective cutting length |

6500 mm + (X) |

||||

|

Rails length |

9000 mm + (X) |

||||

|

Cutting speed |

1~6000 mm/min |

||||

|

Rapid speed |

15000 mm/min |

||||

|

Power supply |

3 phases, 220V, 50~60Hz, 3KVA or on request |

||||

|

CNC controller : Hypertherm Edge Connect

|

|||||

|

Standard |

Oxy-Fuel cutting

|

||||

|

|

|||||

|

Option |

1.Add Motorized Oxy-Fuel torch |

2.Oxy-Fuel cutting torch height sensor (capacitive) |

||

|

3.Zinc Powder marking torch |

4.Water spray |

|||

|

5.Electrical ignition unit |

6.Rail's extension unit : Per 3000mm/unit (X) |

|||

|

7.Plasma |

Hypertherm Hyspeed plasma MAXPRO200(200A) |

|||

|

Powermax 85 plasma(85A), Powermax 105 plasma (105A) |

||||

|

HYPERTHERM High performance plasma |

XPR-170(170A) XPR-300(300A) HPR-400XD(400A) |

|||

|

Other brand or model |

||||

|

8. Plasma height sensor: Sensor THC |

||||